We utilizes a batch fabrication structure that allows correspondence with the customers 24 hours a day.

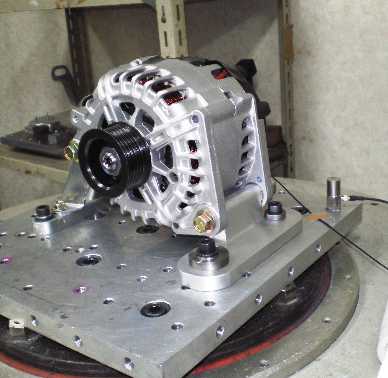

We achieve a high level of quality and meet the demands for cost reduction by utilizing a wide variety of press tooling techniques to meet the customers' demands.

Thus we are able to provide the optimum cost and short lead-time.

We produce more than 3,000 prototypes each year.

Lead-time is normally 1 week. We are supported by automotive, transportation machinery, industrial machinery, and many other Japanese core manufacturers.

We are absolutely confident in our capability to reduce lead-time and cost, and increase the level of quality in prototype part fabrication and to mass production.

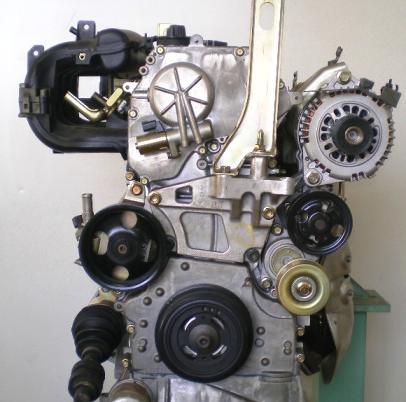

We hold meetings on a regular basis to bring in ideas to improve productivity from the very beginning of the tooling designing.

During this stage, possible oncoming concerns are brought up to smoothly transfer from prototype to mass production.

All concerns are brought up to the customer's attention as a proposition for mass production.

Numerical proof is needed to support any cost reduction and lead-time reduction ideas.

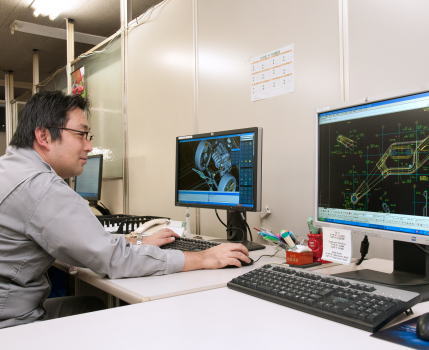

It is vital to have the layout equipment such as 3D picking and modeling to have a layout of the parts in volume, speed, and accuracy to meet a short lead-time.

Our CNC (Computer Numerical Control) screen layout system allow automated layout to accommodate the needs of stable quality condition in a mass production environment.

The process innovation derived from our proud "group of 3D Data process" has made the "super condensed process" or "unsurpassable condensed lead-time" and makes vertical mass production launch possible.

With our experience in automotives, and our increased volume of business outside of automotives, we are consistently increasing our knowledge.

We are equipped with press stamping, welding (A/W, P/W, and S/W), assembly, ED painting, and surface treatment.

We strive to attain customer satisfaction and trust through our high level of quality.

Our US subsidiary, KI(USA) Corp., is ISO/TS16949 certified. KI(USA) is also equipped with the same type of equipment as Keiaisha is and meets customers' delivery and quality requirements.