Information about the Main Plant Equipement

Major Equipement List

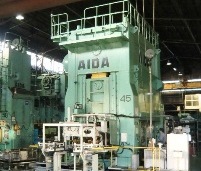

Stamping Machine

| Capacity(ton) | Name | Equipement | Manufacturer | Number owned |

| 35 | Single C-clamp Press | TDM | AMADA | 1 |

| 55~80 | High Flex | TDM | AIDA | 5 |

| 100 | High Flex | TDM | AIDA | 2 |

| 110 | Crank Less | TDM | KOMATSU | 2 |

| 150 | High Flex | TDM | AIDA | 1 |

| 200 | 4-point Press Crank Less | TDM | AIDA | 3 |

| 300 | 2-point Link Motion | TDM | AIDA | 3 |

| 350 | Double Crank | TDM | AIDA | 1 |

| 400 | 2-point Link Motion | TDM | AIDA | 1 |

| 500 | Four Crank Less Press | TDM | AIDA | 4 |

| *250 | Transfer | TRF | KOMATSU | 1(*1) |

| 300 | 3D Transfer | TRF | AIDA | 1 |

| 500 | 3D Transfer | TRF | AIDA | 2 |

| 600 | 3D Transfer | TRF | AIDA | 2 |

| *200 | Eccentric | PRG | KOMATSU | 1 |

| *200 | High Flex | PRG | AIDA | 1 |

| *250 | High Promaster | PRG | AIDA | 2 |

| *500 | 2-point Link Motion | PRG | AIDA | 1 |

| *600 | 2-point Link Motion | PRG | AIDA | 1 |

Resistance Welder

| Capacity(KVA) |

Name |

Equipement |

Manufacturer |

Number owned |

| 25~80 |

Spot Projection |

SW・PW |

Panasonic |

81 |

| 90*2 |

Multi spot |

SW |

Toyo Engineering |

3 |

| 100 |

Portable Spot |

SW |

Panasonic |

5 |

| 110 |

Spot 8 special-purpose machine |

|

KI |

1 |

| 110 |

Portable Spot |

SW |

DENGENSHA |

9 |

| 110 |

Trans |

|

DAIDEN |

3 |

| 125 |

Portable Spot |

SW |

DENGENSHA |

7 |

| 130 |

Projection |

PW |

DENGENSHA |

1 |

| 150 |

Spot |

SW |

MIYACHI |

1 |

| 150 |

Projection |

PW |

NASTOA |

1 |

| 150 |

Multi Spot |

SW |

NASTOA |

1 |

| 150 |

ポータブルスポット |

SW |

DENGENSHA |

5 |

| 165 |

Projection |

PW |

HITACHI |

1 |

| 200 |

Projection |

PW |

DENGENSHA |

3 |

| 300 |

Projection |

PW |

Panasonic |

1 |

| 350 |

Projection |

PW |

NASTOA |

1 |

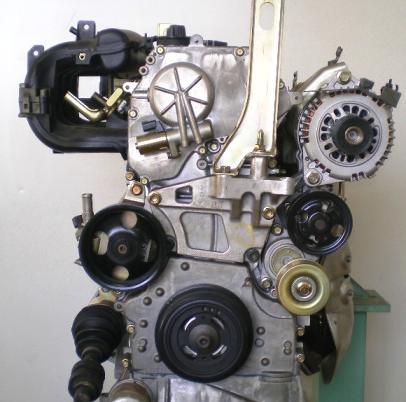

Arc Welding Machine

| Name |

Equipement |

Manufacturer |

Number owned |

| CO2 Automatic Welding Machine |

AW |

KI |

4 |

| Power CO2 (Hand) |

AW |

Panasonic |

28 |

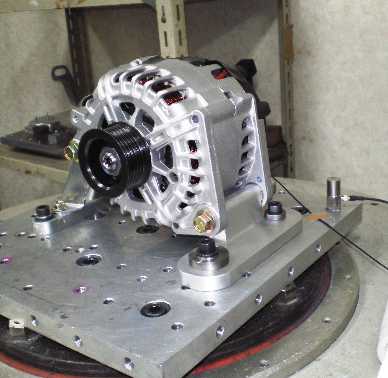

Robotic Equipement

| Name |

Use |

Manufacturer |

Number owned |

| Handling, Robot |

Press |

FUJIKOSHI |

1 |

| Handling, Robot |

Assembly |

KAWASAKI |

8 |

| XY 2-axis Robot |

|

Panasonic |

4 |

| XYZ 3-axis Robot |

|

Panasonic |

1 |

| Robot Arc |

|

DAIHEN |

26 |

| Robot Arc (BAR ASSY-CROSS) |

|

Panasonic |

15 |