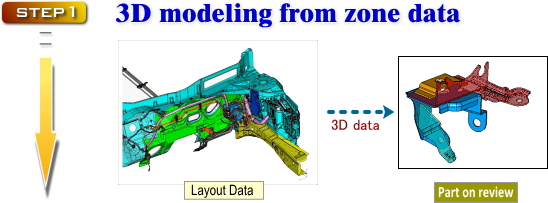

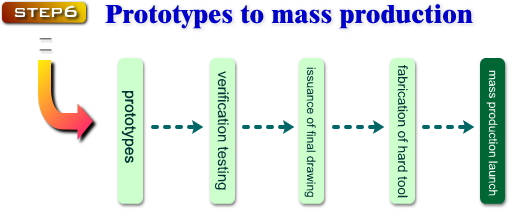

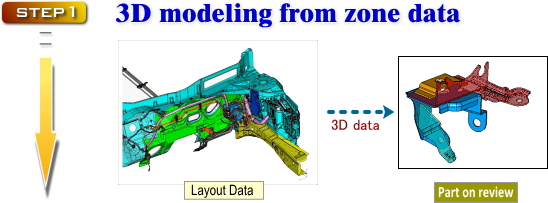

Proposal process that goes from data to a press stamped prototype product

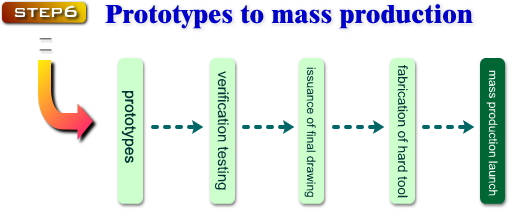

Keiaisha Prototype Fabrication Group provides prototypes and mass production parts for automobiles, construction machineries, industrial machineries, etc.

Please contact us by phone at +81-45-804-8812 or fill out the inquiry form.

Please fill out your information.

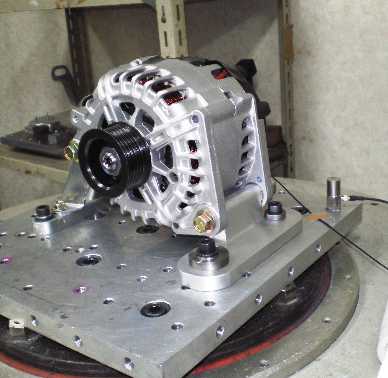

Material: ADC12

Method: aluminum die cast

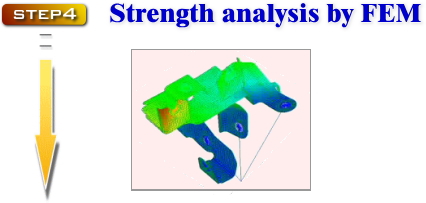

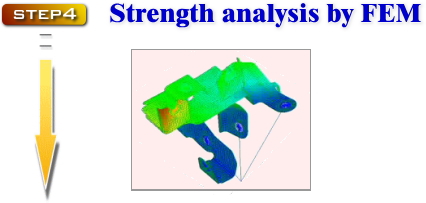

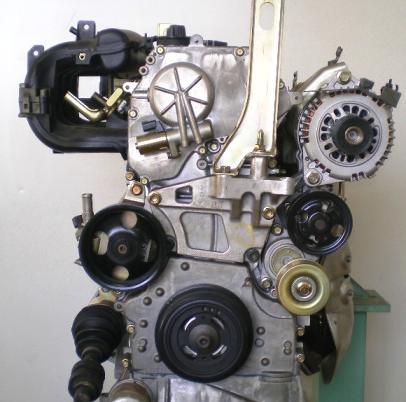

Inspect resonant frequency, auxiliary machine vibration, bracket emergence stress, etc. and compare with the results from the actual machine.

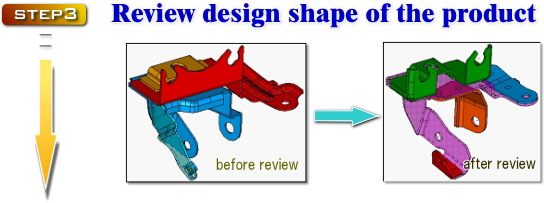

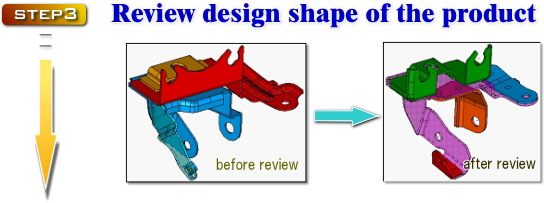

Validate customer's criteria using CAE analysis and determine the suggested design shape.

Apply 107 time resonant frequency and stress measurement, validate for the existence of cracks. This would allow to create an improved shape easily.

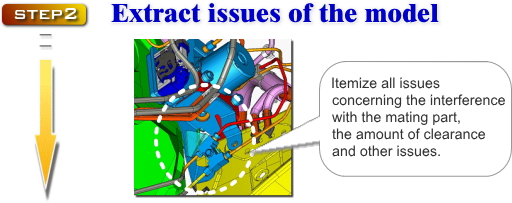

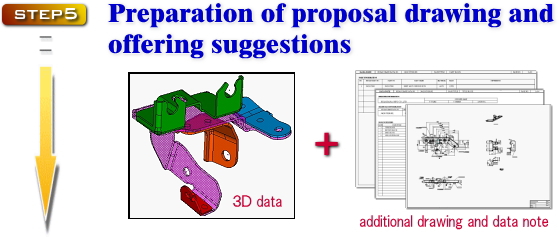

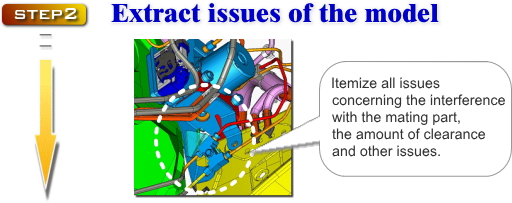

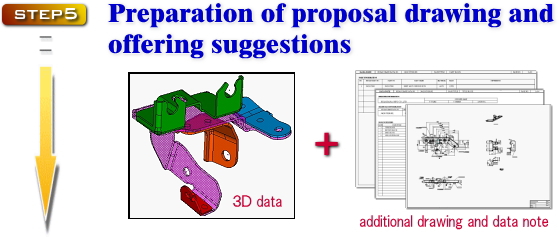

The simulation study on 3D CAD make interference at assembly visible. The issue can be resolved beforehand to make smooth production launch possible.